In modern machining, steady rests have a crucial role to play in stabilizing and ensuring accuracy during turning processes. These crucial components offer support for workpieces that are cylindrical, which reduces vibrations, and allows high-precision turning. As technology advances, companies now offer a variety of custom solutions for lathes, like hydraulic self-centering, steady rests, zero point clamping supports broad arms, narrow arms and an array of accessories for stable rests.

This article examines the most recent developments in steady rests and their accessories, focusing on their impact on improving efficiency quality, precision, and efficiency within the machining industry.

Hydraulic Self-Centering Steady Rests: Revolutionizing Machining

For the old steady rests, manual adjustments were required to place the workpiece properly. They are now auto-centering hydraulic steady rests have transformed the process by providing automated and precise alignment. These high-tech steady rests employ hydraulic systems to clamp and center parts without manual intervention, significantly reducing setup time and ensuring consistent results.

The Benefits of HTML0 Hydraulic self-centering steady rests:

Automatic Adjustment eliminates the need to manually align, thereby increasing effectiveness.

Increased Precision: Ensures repeatability in mass production.

Better Vibration Control It reduces the risk of machine errors and extends tool life.

Time-Saving speeds up the machining process and optimizes the workflow.

Hydraulic self-centering stable rests are particularly useful for high-volume production and high-precision machining they are essential for modern lathe operations.

Zero-Point Clamping Support: A Game-Changer in Workholding

A one-point clamping technique is an innovative method created to facilitate the workpiece's setup. It allows quick and precise positioning of workpieces reducing downtime and increasing overall productivity.

The advantages of zero-point clamping Systems:

Quick Workpiece Changeovers • Reduces setup time and improves efficiency.

Strong Clamping Force This ensures a strong and steady support.

Higher Accuracy Allows exact line-up of components.

Versatility: Suitable for an array of turning applications.

Through the integration of the zero-point clamping support together with stationary rests Manufacturers can achieve maximum stabilities and optimal conditions for machining.

Narrow Arms: Enhancing Accessibility and Performance

In the case of machining difficult or narrow parts, traditional steady rests can often block the path of tooling. To remedy this, manufacturers have developed small-arm steady rests that provide better access, yet maintain an identical level of support and stability like traditional models.

Why Should You Choose Narrow-Arm Steady Rests?

Compact Design: This design allows for better access to tight areas of machining.

Unobstructed Tool Path Reducing interference cutting tools.

Perfect for small or complex parts The system provides the proper support without compromising machine space.

They are effective in industries requiring precise turning of thin or irregularly shaped components.

Equipment for Steady Rests to Expand Functionality

A variety of tools for steady rests increase their effectiveness by providing more flexibility and customisation for various machining tasks. Some essential accessories include: Soporte de sujeción de punto cero

1. Pressure Adjustment Systems

The ability to fine tune the steady rest's clamping force.

It ensures that the pressure is safe and effective on high-strength, delicate or delicate materials.

2. Contact Pads and Special Coatings

Protects the workpiece surface from the possibility of damage.

Reduces wear and tear on the steady rest.

3. Coolant and Lubrication Systems

It keeps the workpiece as well as the rest of the components in good condition.

Helps prevent overheating and prolong the durability of tools.

4. Automation and Sensors

Provides real-time monitoring for regular rest positions.

Increases efficiency of automated production lines.

With the help of specific accessories, manufacturers can tailor their steady rest systems according to particular machine requirements.

Custom Solutions for Lathes customized to the industry's requirements

No two machining applications are exactly alike and that's the reason custom products for lathes are getting more and more popular. Manufacturers now offer custom-designed steady rests as well as workholding solutions to meet the distinct needs of various industries such as automotive, aerospace and heavy production of machines.

The most important aspects of Custom Lathe Solutions:

The Custom Dimensions and Designs Customized to meet specific requirements of the machine or workpiece.

Materials and Coating Options: Optimized for different machines and environments.

Integration with Automation Systems: Enhances productivity in modern manufacturing environments.

Custom-built stable rests and accessories let businesses maximise productivity while ensuring precision results They are an essential asset for any machining workshop.

Conclusion: The Future of Steady Rest Technology

The advancement of the hydraulic self-centering steady rests, zero-point clamping supports, narrow arms and customized lathe solutions has transformed machining efficiency and accuracy. These developments help manufacturers reduce time to set-up, increase accuracy, and optimize workflow while ensuring competitiveness an ever-changing industry.

In investing in top-quality steady stops and accessories manufacturing companies can enhance their production capabilities, improve the precision of their machining, and extend the lifespan of both workpieces and tools. As the technology advances, custom and automated solutions will play a more critical role in shaping the future of the lathe industry.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Susan Dey Then & Now!

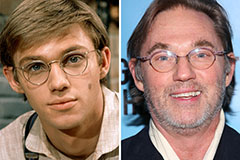

Susan Dey Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!